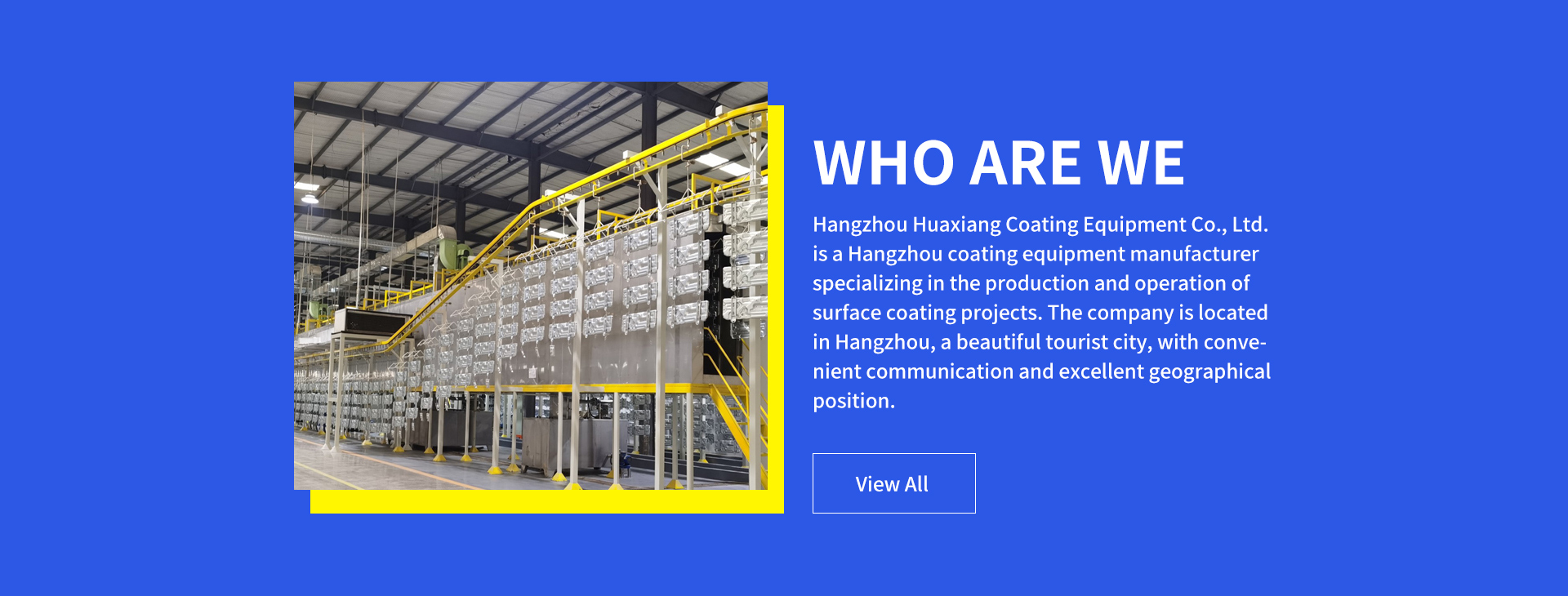

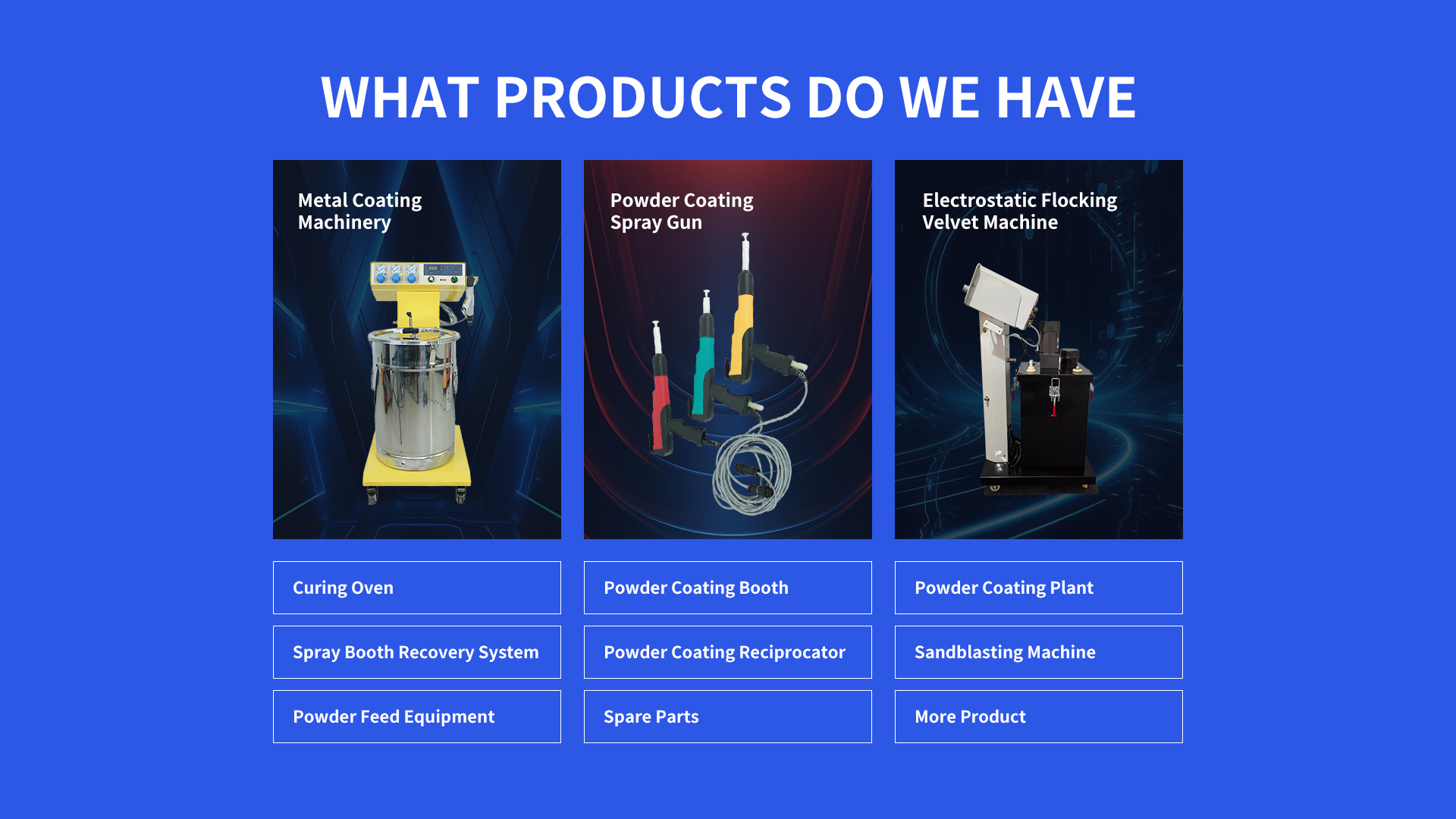

1. Introduction to Commercial Powder Coating Spray Booths

A Commercial Powder Coating Spray Booth is an enclosed workspace designed to contain and control the powder application process. Key components include ventilation systems, filters, electrostatic grounding, and powder recovery units. These booths ensure safe, efficient coating by managing airflow, minimizing overspray, and capturing excess powder for reuse.

2. Applications of Commercial Powder Coating Spray Booths

Used in automotive repair, industrial manufacturing, and metal fabrication, these booths coat items like machinery parts, automotive frames, and architectural metalwork. They are critical for industries requiring contamination-free environments, consistent finishes, and compliance with workplace safety regulations.

3. Cost of Commercial Powder Coating Spray Booths

Prices range from 5,000forbasicsingle−stageboothsto50,000+ for large, fully automated systems. Mid-range models (15,000–30,000) often include advanced filtration, energy-efficient fans, and powder recycling features. Customization for size or airflow requirements can increase costs.

4. Proper Use of Commercial Powder Coating Spray Booths

Pre-clean surfaces to eliminate dust and oils. Maintain optimal airflow settings to ensure even powder distribution. Ground the booth and workpiece to prevent electrostatic discharge. After coating, activate recovery systems to collect unused powder. Clean filters and surfaces regularly to prevent blockages.

5. How to Choose a Commercial Powder Coating Spray Booth

Assess workspace size, production volume, and part dimensions. Opt for booths with HEPA filters for fine powder containment. Prioritize energy-efficient ventilation and OSHA-compliant designs. Modular booths allow scalability, while stainless steel builds enhance durability.

6. Safety Precautions for Commercial Powder Coating Spray Booths

Ensure proper ventilation to avoid inhaling airborne particles. Use explosion-proof lighting and equipment in flammable environments. Operators must wear PPE, including respirators and anti-static clothing. Regularly inspect electrical systems and grounding mechanisms.

7. Design Advantages of Commercial Powder Coating Spray Booths

Modern booths feature optimized airflow patterns to reduce powder waste. Powder recovery systems lower material costs by recycling up to 95% of overspray. Insulated panels improve temperature control, while ergonomic layouts enhance operator efficiency.

8. FAQs About Commercial Powder Coating Spray Booths

Q: How to prevent powder overspray contamination?

A: Use high-efficiency filters and maintain consistent airflow management.

Q: Can booths handle large or irregularly shaped parts?

A: Yes, customizable booth sizes and adjustable powder containment systems accommodate diverse projects.

Q: What maintenance is required?

A: Clean filters weekly, inspect fans monthly, and replace worn powder recovery components.

Q: Are these booths energy-efficient?

A: Advanced models use variable-speed fans to reduce energy consumption in powder coating.

Q: How to ensure fire safety?

A: Install spark detection systems and avoid flammable powder accumulation in ducts.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com